PLASTIC APPLICATIONS AND OUTLETS

Appropriately selected WAXOLINE® polymer-soluble dyes give excellent all-round performance in: PS (Polystyrene), SAN, ABS, PMMA, PC, PETP and PETB, POM, unplasticised PVC and PPO. WAXOLINE® solvent dyes contribute resistances (strengths) against different phenomena that affect dye’s performance.

- Light fastness: persistence of a colour after having received a certain amount of UV radiation.

- Chemical fastness: colour resistance in chemically aggressive environments (acidic or basic).

- Heat fastness: colour resistance to temperature, mainly during processing.

- Migration fastness: migration of pigment.

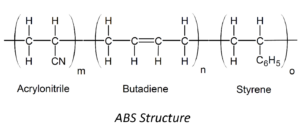

ABS (Acrylonitrile butadiene styrene)

What is acrylonitrile butadiene styrene?

Also called engineering plastic, because it is a plastic whose elaboration and processing is more complex than common plastics, such as polyolefins (polyethylene, polypropylene).

Chemical properties of abs acrylonitrile butadiene styrene

- Very good resistance to dilute acids and alkalis.

- Moderate resistance to aliphatic hydrocarbons.

- Low resistance to aromatic hydrocarbons, halogenated hydrocarbons, and alcohols.

Mechanical properties of abs acrylonitrile butadiene styrene

- Acrylonitrile blocks provide stiffness, resistance to chemical attack and high temperature stability as well as toughness.

- Butadiene blocks provide toughness at any temperature. Ductility, impact, and fusion resistance.

- The styrene block provides mechanical strength, rigidity, hardness, gloss, and fluidity.

Applications of acrylonitrile butadiene styrene ABS

- Automotive parts (dashboards, bumpers, etc.)

- Household appliances

- Office machines, computer cases and telephones.

- Toys, etc.

Advantages of ABS (Acrylonitrile butadiene styrene)

It can be used in alloys with other plastics. For example, ABS with PVC gives a plastic of high flame resistance that allows it to find wide use in the construction of televisions.

Acrylonitrile butadiene styrene (abs) can be processed by injection molding and extrusion processes.