PLASTIC APPLICATIONS AND OUTLETS

Appropriately selected WAXOLINE® polymer-soluble dyes give excellent all-round performance in: PS (Polystyrene), SAN, ABS, PMMA, PC, PETP and PETB, POM, unplasticised PVC and PPO. WAXOLINE® solvent dyes contribute resistances (strengths) against different phenomena that affect dye’s performance.

- Light fastness: persistence of a colour after having received a certain amount of UV radiation.

- Chemical fastness: colour resistance in chemically aggressive environments (acidic or basic).

- Heat fastness: colour resistance to temperature, mainly during processing.

- Migration fastness: migration of pigment.

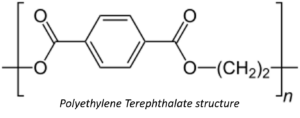

PET (Polyethylene terephthalate)

What is Polyethylene Terephthalate?

Polyethylene terephthalate more commonly known as PET, is an aromatic polyester. Its technical name is polyethylene terephthalate or polyethylene terephthalate, and it is part of the thermoplastics group, which is why it can be recycled.

Due to its impermeability to gases, PET covers almost 100% of the market for returnable and non-returnable bottles for carbonated beverages.

What is Polyethylene Terephthalate used for?

Among the multiple uses given to PET (Polyethylene terephthalate), due to its excellent durability, dimensional stability and insensitivity to humidity, the use given to it in the manufacture of carbonated beverage containers and food packaging stands out, since it does not deteriorate or cause toxicity effects to these products:

- Carbonated Beverages

- Purified Water

- Oil

- Canned Food

- Cosmetics

- Detergents and Chemicals

- Pharmaceuticals

What are the ADVANTAGES of PET (Polyethylene terephthalate)?

- Processable by blow molding, injection, and extrusion.

- Suitable for producing bottles, films, sheets, plates, and parts.

- Transparency (although it admits dye fillers) and gloss with magnifying glass effect.

- High wear resistance.

- Very good sliding coefficient.

- Good chemical and thermal resistance.

- Very good barrier to CO2, acceptable barrier to O2 and humidity.

- Compatible with other barrier materials that improve the overall barrier quality of the containers and therefore allow their use in specific markets.

- Recyclable, although it tends to decrease in viscosity with thermal history.

- Approved for use in products that must be in contact with food products.

- Excellent mechanical properties.

- Sterilizable by gamma rays and ethylene oxide.

- Good cost / performance ratio.

- Ranked as No.1 in recycling.

- Light weight.

What are the advantages of SAN (Acrylonitrile styrene)?

- Is transparent, amorphous in structure and easily processed.

- Has a better impact, tensile and flexural properties than styrene homopolymers (characteristics provided by acrylonitrile).

- It is resistant to oils, greases, formaldehyde, gasoline, and hydrochloric acid.

- It’s not chemically attacked by water.

- It has a high surface gloss.

- It has very low water absorption.

- Low manufacturing cost and easy processing.

- High stiffness.

- Very good thermal resistance.