Polystyrene is a versatile a colorless, transparent thermoplastic, used to make a wide variety of consumer products. Polystyrene can be solid or foamed. As a hard, solid plastic, it is often used in products that require clarity, such as food packaging and laboratory ware. Polystyrene is which is commonly used to make foam board or beadboard insulation and a type of loose-fill insulation consisting of small beads of polystyrene.

When combined with various colorants, additives or other plastics, polystyrene is used to make appliances, electronics, automobile parts, toys, gardening pots and equipment and more.

Appropriately selected WAXOLINE™ polymer-soluble dyes give excellent all-round performance in PS (Polystyrene).

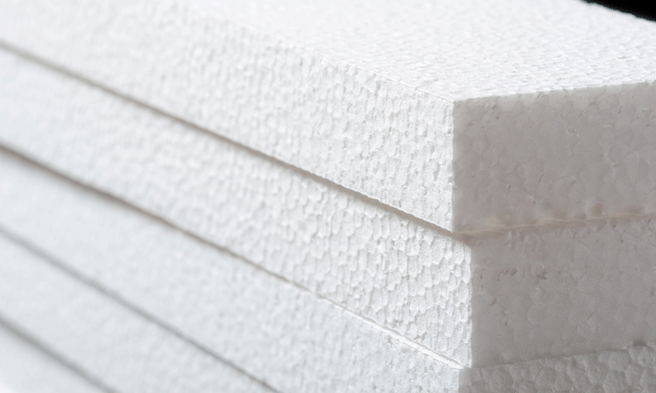

What Is Expanded Polystyrene (EPS)

Polystyrene is also made into a foam material, called expanded polystyrene (EPS).

Expanded polystyrene (EPS) refers to a rigid, tough, and lightweight thermoplastic product. EPS is composed of small pre-expanded polystyrene beads that are fused together, generally white. Can be more than 95 percent air and is valued for its insulating and cushioning properties.

EPS is highly resistant to biological corrosion and is widely used to make home and appliance insulation, lightweight protective packaging, surfboards, foodservice and food packaging, automobile parts.

It also minimizes the effects of moisture and water vapor, which is why it is used as an insulation product.

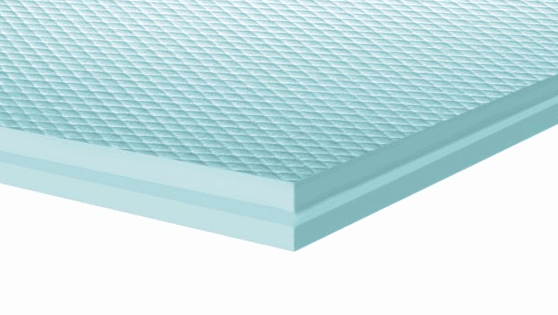

What is Extruded Polystyrene – XPS

Extruded polystyrene (XPS) is also a thermoplastic polymer, most commonly used as foam board insulation. Extruded polystyrene has a closed cell structure and is often stronger, with a higher mechanical performance and is, in principle, often more expensive than EPS. Its density range is about 28–45 kg/m3. XPS is produced from the same base materials as EPS and therefore also has crude oil at its basis. Polystyrene is made by stringing together, or polymerizing, styrene, a building-block chemical used in the manufacture of many products.

Polystyrene uses & benefits

Polystyrene in Appliances

Refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, blenders – these and other appliances often are made with polystyrene (solid and foam) because it is inert (doesn’t react with other materials), cost-effective and long-lasting.

Polystyrene in Automotive

Polystyrene (solid and foam) is used to make many car parts, including knobs, instrument panels, trim, energy absorbing door panels and sound dampening foam. Foam polystyrene also is widely used in child protective seats.

Polystyrene in Electronics

Polystyrene is used for the housing and other parts for televisions, computers and all types of IT equipment, where the combination of form, function and aesthetics are essential.

Polystyrene in Foodservice

Polystyrene foodservice packaging typically insulates better, keeps food fresher longer and costs less than alternatives.

Polystyrene in Insulation

Lightweight polystyrene foam provides excellent thermal insulation in numerous applications, such as building walls and roofing, refrigerators and freezers, and industrial cold storage facilities. Polystyrene insulation is inert, durable and resistant to water damage.

Polystyrene in Medical

Due to its clarity and ease of sterilization, polystyrene is used for a wide range of medical applications, including tissue culture trays, test tubes, petri dishes, diagnostic components, housings for test kits and medical devices.

Polystyrene in Packaging

Polystyrene (solid and foam) is widely used to protect consumer products. CD and DVD cases, foam packaging peanuts for shipping, food packaging, meat/poultry trays and egg cartons typically are made with polystyrene to protect against damage or spoilage.