PLASTIC COLORATION (MASTERBATCH)

Basic concepts:

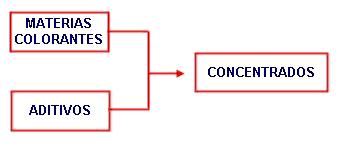

There are various techniques for coloring thermoplastic resins: among them concentrates or masterbatches stand out, because they offer many advantages to the transformers that use them. Despite the simplicity of use, the concentrates have complex compositions of colorants and / or additives, which obey rigid criteria in their selection and incorporation. To start the discussion on masterbatches we must address three basic concepts:

1. Coloring matter

2. Concentrates

3. Aditives

PLASTIC COLORATION

- COLORING MATTERS:

These are chemical substances that, once incorporated, give color to a substrate. Colorants can be classified into two categories: colorants themselves and pigments. The latter, in turn, can be divided into two classes: organic and inorganic pigments.

– Colorants: They are organic colorants soluble in the application medium. They have a low refractive index, high tinting power, low light fastness, temperature and high brightness.

– Pigments: They are insoluble colorants. They have a high refractive index and the application medium does not affect them chemically or physically. High light fastness and temperature.

COLORS CAN BE USED IN THE FOLLOWING PLASTICS:

Rigid PVC

Polypropylene

PMMA

ABS/SAN

PET

Nylon and Polycarbonate

POLYSTYRENE:

Polystyrene (PS) is a thermoplastic polymer that is obtained from the polymerization of monomeric styrene. There are four main types: crystal PS or GPPS (General Purpose Polystyrene), which is transparent, rigid and brittle; high impact polystyrene or HIPS (from the English: High Impact Polystyrene), is resistant to impact and opaque whitish; the expanded polystyrene or EPS (from English: Expandable Polystyrene; PSE in French), very light; and extruded polystyrene, similar to expanded polystyrene but denser and more waterproof. The main applications of anti-shock PS and glass PS are the manufacture of containers by extrusion-thermoforming, and of various objects by injection molding. Expanded and extruded forms are used mainly as thermal insulators in construction and to form protective shells in the packaging of fragile objects to protect them. EPS is also used for the production of fish boxes or refrigerators for the transport of vaccines, due to its insulating capacity.

RIGID PVC:

Rigid PVC is a thermoplastic with an amorphous structure that is distinguished by its great resistance to chemical agents and its excellent mechanical properties. It has excellent chemical stability and excellent fire resistance (self-extinguishing). It has a remarkable resistance against dilute and concentrated acids. It is also a good electrical insulator. It absorbs little water and can be soldered and glued. Since its applications are currently under regulation in many countries for ecological reasons, it is often replaced by polypropylene.

POLIPROPILENO:

Polypropylene (PP) is the partially crystalline thermoplastic polymer that is obtained from the polymerization of propylene (or propene). It belongs to the group of polyolefins and is used in a wide variety of applications including food packaging, fabrics, laboratory equipment, automotive components and transparent films. It has great resistance against various chemical solvents, as well as against alkalis and acids.

PMMA:

Methacrylate, also known by its acronym PMMA, is one of the engineering plastics. The acrylic plate is obtained from the polymerization of methyl methacrylate and the most common presentation found in the plastics industry is in granules (“pellas” in Spanish; “pellets” in English) or in plates. The granules are for the injection or extrusion process and the plates for thermoforming or for machining.

It competes in applications with other plastics such as polycarbonate (PC) or polystyrene (PS), but acrylic stands out against other transparent plastics in terms of weather resistance, transparency and scratch resistance.

Due to these qualities, it is used in the automobile industry such as car headlights, lighting, cosmetics, entertainment, construction and optics, among many others. In the world of medicine, polymethylmethacrylate resin is used for the manufacture of bone and dental prostheses and as a powder additive in the formulation of many of the pills that we can take orally. In this case, it acts as a retarder to the action of the drug so that it is progressive.

ABS/SAN:

Acrylonitrile butadiene styrene or ABS (for its acronym in English Acrylonitrile Butadiene Styrene) is a very resistant plastic to impact (blows) widely used in automotive and other industrial and domestic uses. It is an amorphous thermoplastic.

The acrylonitrile blocks provide rigidity, resistance to chemical attack and stability at high temperature as well as hardness, properties that are highly appreciated in certain applications such as heavy equipment or electronic devices.

Butadiene blocks, which is an elastomer, provide toughness at any temperature. This is especially interesting for cold environments, in which other plastics become brittle. The styrene block provides mechanical strength and rigidity.

This mixture of properties, called, by chemical engineers, synergy, indicates that the final product contains better properties than the sum of them. ABS is a clear example of material design in chemical engineering, which seeks to achieve composites of existing materials as opposed to developing completely new materials

PET:

Polyethylene terephthalate, polyethylene terephthalate, polyethylene terephthalate or polyethylene terephthalate (better known by its acronym in English PET, polyethylene terephthalate) is a type of plastic widely used in beverage and textile packaging. Some companies manufacture PET and other polyesters under different trademarks that have come into common use, for example, in the United States and the United Kingdom they use the names Mylar and Melinex.

Chemically, PET is a polymer that is obtained through a polycondensation reaction between terephthalic acid and ethylene glycol. It belongs to the group of polyesters called synthetic materials.

It is a linear thermoplastic polymer, with a high degree of crystallinity. Like all thermoplastics, it can be processed by extrusion, injection, injection and blowing, preform blowing and thermoforming. To avoid the excessive growth of spherulites and crystal lamellas, this material must be rapidly cooled, thereby achieving greater transparency. The reason for their transparency when cooling rapidly is that the crystals are not fully developed and their size does not interfere (“scattering”) with the path of the wavelength of visible light, according to quantum theory.

POLYAMIDE:

Nylon 6.6 1 2 (nylon 6-6, nylon 6/6, or nylon 6.6) is a type of polyamide or nylon. This and nylon 6 are the two most common for the textile and plastics industries. Nylon 6,6 is made of two monomers, each with 6 carbon atoms, hexamethylenediamine and adipic acid, which give nylon 6,6 its name.

Nylon -6,6 is synthesized by polycondensation of hexamethylenediamine and adipic acid. Equivalent amounts of hexamethylenediamine and adipic acid are combined with water in a reactor. This is crystallized to make nylon salt, an ammonium / carboxylate mixture. The nylon salt enters a reaction vessel where the polymerization process takes place in batches or continuously.

n HOOC- (CH2) 4-COOH + n H2N- (CH2) 6-NH2 → [-OC- (CH2) 4-CO-NH- (CH2) 6-NH-] n + (2n-1) H2O La Elimination of the water drives the reaction towards polymerization through the formation of amide bonds from the acid and amine functions. This forms molten nylon 66. It can be extruded and granulated at this point or spun directly into fibers by extrusion through a spinneret (a small metal plate with fine holes) and cooled to form filaments.

POLYCARBONATE:

Polycarbonate is a group of thermoplastics, easy to work, mold and thermoform, and is widely used in modern manufacturing. The name polycarbonate is due to the fact that it is a polymer that has functional groups linked by carbonate groups in a long molecular chain.

Carbon monoxide was also used to synthesize carbonates on an industrial scale and produce diphenyl carbonate, which is then esterified with a diphenolic derivative to obtain polyaromatic carbonates.

Taking into account the synthesis of the carbonate group, polycarbonates can be divided into polyaromatic carbonates and polyaliphatic carbonates. The latter are the product of the reaction of carbon dioxide with epoxides. Taking into account the thermodynamic stability of carbon dioxide, it is required to use catalysts.

ADVANTAGES:

Extremely high impact resistance.

Great transparency.

High strength and rigidity.

High resistance to thermal deformation.

High dimensional stability, that is, high resistance to creep.

Good electrical insulation properties.

High resistance to the elements, with protection against ultraviolet rays.